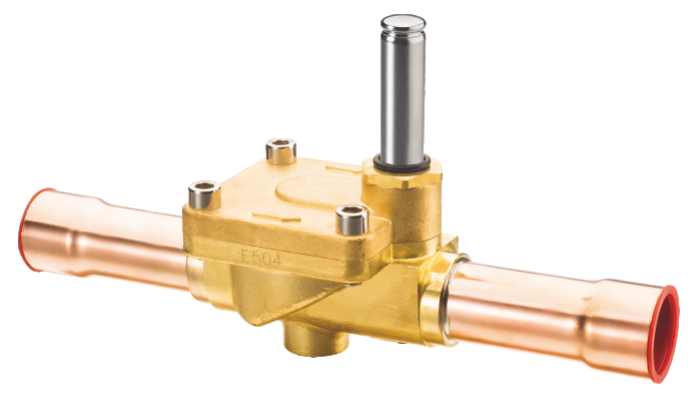

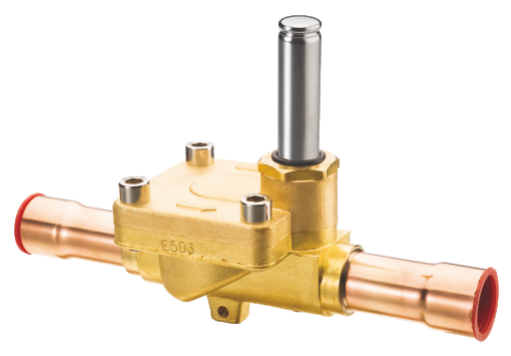

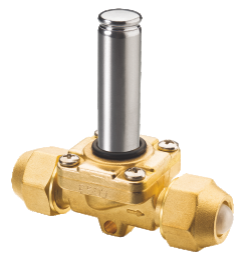

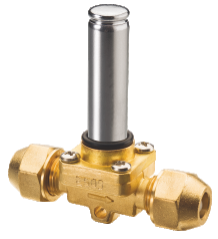

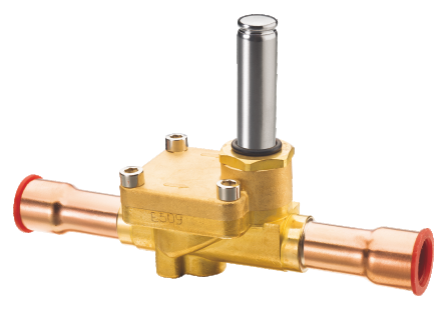

Model EVR solenoid valve

·Model HV solenoid valve is used on the piping of liquid, suction gas or hot air on the freezing, cold storage and air conditioner units. ·The valve seat and seals of Model HV solenoid valve have excellent sealing performance. ·Model HV solenoid valve could be supplied with coils of varied voltage. ·Model HV solenoid valve could be supplied in assembly or in separate components, that is, the valve body and the coil could be supplied separately.

·Model HV solenoid valve is a one-step on/off or two-step on/off solenoid valve, which is applicable to one-way flow.

| Model | Connection Type | △P(bar) | Max.Operating Pressure | Kv(㎥/h) | ||

| Flare | Welded | Min. | MOPO LiquidMOP | |||

| EVR3-2 | 1/4 SAE | 1/4 ODF | 0.0 | 31 | 45 | 0.16 |

| EVR3-3 | 3/8 SAE | 3/8 ODF | 0.0 | 0.27 | ||

| EVR6-3 | 3/8 SAE | 3/8 ODF | 0.05 | 0.8 | ||

| EVR6-4 | 1/2 SAE | 1/2 ODF | 0.8 | |||

| EVR10-4 | 1/2 SAE | 1/2 ODF | 1.9 | |||

| EVR10-5 | 5/8 SAE | 5/8 ODF | 1.9 | |||

| EVR15-5 | 5/8 SAE | 5/8 ODF | 0.2 | 2.6 | ||

| EVR15-6 | 3/4 SAE | 3/4 ODF | 2.6 | |||

| EVR15-7 | —— | 7/8 ODF | 2.6 | |||

| EVR20-7 | —— | 7/8 ODF | 5.0 | |||

| EVR25-9 | —— |  | 10 | |||

1) Kv: The flow rate (m³/h) of water of density 1t/m³ passing through the solenoid valve under the pressure differential of 100 KPa.

2) The MOPD of gaseous medium is about 1 bar higher than that of liquid.

| Model | Nominal Refrigerating Capacity kW | ||||||||

| Liquid | Air Suction | Hot Vapor | |||||||

| R22\R407C | R134a | R404A\R507 | R22\R407C | R134a | R404A\R507 | R22\R407C | R134a | R404A\R507 | |

| EVR3 | 5.40 | 5.00 | 3.80 | —— | —— | —— | 2.0 | 2.00 | 2.00 |

| EVR6 | 16.10 | 14.80 | 11.20 | 1.80 | 1.30 | 1.6 | 7.4 | 5.90 | 6.00 |

| EVR10 | 38.20 | 35.30 | 26.70 | 4.30 | 3.10 | 3.90 | 17.50 | 13.90 | 14.30 |

| EVR15 | 52.30 | 48.30 | 36.50 | 5.90 | 4.20 | 5.30 | 24.00 | 19.00 | 19.60 |

| EVR20 | 101.0 | 92.80 | 70.30 | 11.40 | 8.10 | 10.20 | 46.20 | 36.60 | 37.70 |

| EVR25 | 201.0 | 186.0 | 141.0 | 22.80 | 16.30 | 20.40 | 92.30 | 73.20 | 75.30 |

The working condition the nominal refrigerating capacity of liquid and air suction is as follows:

Evaporation Temperature: te = -10℃;

Liquid Temperature before Valve: t1 = +25℃;

Pressure Drop after Solenoid Valve: △P = 15KPa

The working condition the nominal refrigerating capacity of hot vapor is as follows:

Condensation Temperature: tc = +40℃;

Pressure Drop after Solenoid Valve: △P = 80KPa;

Hot Vapor Temperature: th = +65℃;

Liquid Refrigerant Overcooding: △t = 4K

| pplicable Refrigerants: | HCFC or HFC(Customer apecified) |

| Applicable Medium Temperature: | -30℃~+105℃ |

| Application Ambient Temperature of Solenoid | -40℃~+65℃ |

| Standard Voltage of Solenoid | AC 380V.AC 220V/50Hz(Customer design is available) |

| Allowable Voltage Fluctuation for Solenoid | +10%~15% |

| Connection of Solenoid | Standard 3-wire insert connector |

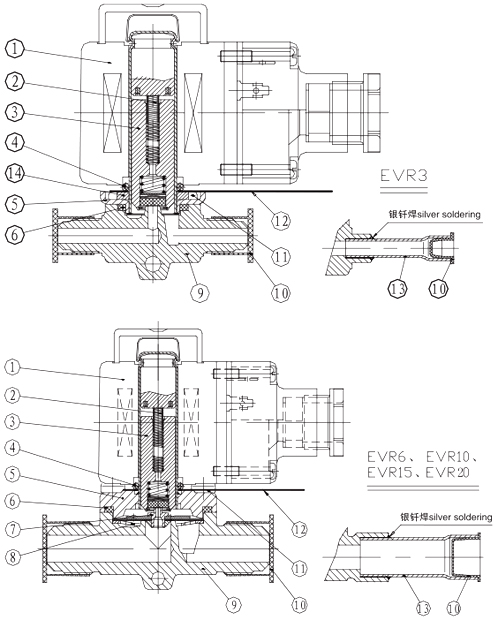

1、solenoid(10W); 2、return spring; 3、iron core component(modified PTFE seal)(imported stainless magnet steel); 4、O-ring(CR); 5、valve bonnet; 6、sealing(CR); 7、valve core(movable)(modified PTFE compound diaphragm); 8、baffle; 9、valve body; 10、cap; 11、fixing screws(4); 12、label; 13、copper tube; 14、steel washer

Model EVR solenoid valve is designed in accordance with following two operating principles:

1. Direct-operated Solenoid Valve

Model EVR 3 is a direct-operated solenoid valve. When the iron core component (3) moves upward by the magnetic force of the solenoid, the solenoid valve will open directly, that is, the solenoid valve could be operated under zero pressure differential.

The sealing valve core (modified PTFE) is directly, mounted on the iron core component

The inlet pressure is applied onto the iron core from the upper side. Therefore, the joint action of the inlet pressure, spring force and self-gravity of the iron core component will close the valve when the solenoid is not energized.

2. Servo-operated Solenoid Valve

Model EVR 10/15/20 are servo-operated solenoid valves with movable valve core (7). The guide valve core diaphragm (modified PTFE compound diaphragm) are mounted on the valve core.

The main valve port and guide valve port closed when the solenoid is not energized. The joint action of the self-gravity of the iron core component, spring force and the pressure differential between inlet and outlet will close valve.

When the solenoid is energized, the iron core component (3) moves upward to open the guide valve on the diaphragm. The moment the pressure on the diaphragm is decreased and the space above the diaphragm is communicated with the outlet of the valve. The pressure differential between the inlet and outlet moves the diaphragm upward and open. Therefore it needs a minimum pressure differential to open the valve and maintain the opening.

When the power is cut off, the guide valve on the diaphragm is closed and the balance hole on the diaphragm will the pressure rise as the same as the inlet pressure. Consequently the diaphragm will move downward to close the main valve port.