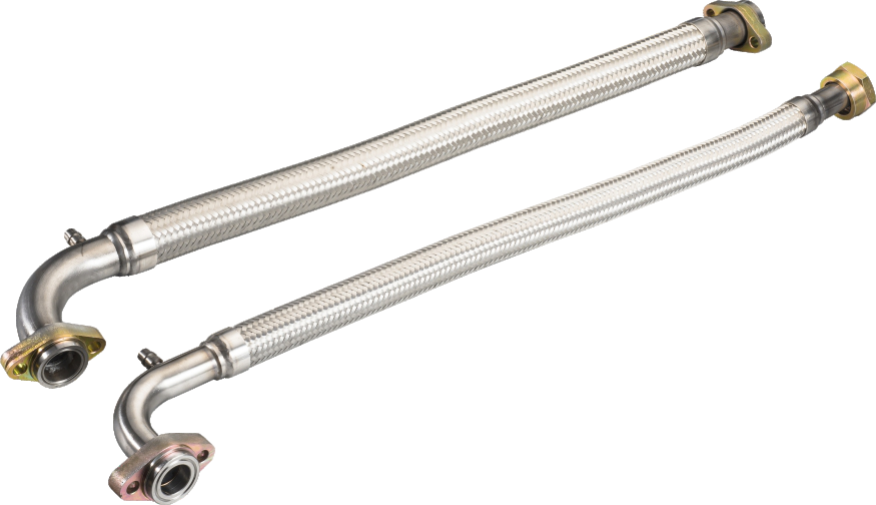

Automotive air conditioner metallic hose

Automotive air conditioner metallic hose is used as a flexible connection between the automotive air conditioner compressor, evaporator and condenser. The metallic hose is capable to withstand the high temperature shock from the air conditioner compressor, and it could absorb any shock and compensate any installation deviation in the cooling circulation loop under an operation condition of high and low pressure and high and low temperature as well as any bumping or vibration in the running vehicle.

| Nominal Bore | Outline Dimension | Max.Working Pressure(MPa) | Min.Bending Radius(mm) | ||||

| (mm) | (in) | E | L | M | Stadic(Rj) | Dynamic(Rd) | |

| 20 | 3/4 | 68 | ≥800 | M27x1.5 | 3.5 | 145 | 325 |

| 25 | 1 | 95 | ≥800 | M42x1.5 | 3.5 | 175 | 400 |

| 32 | 1-1/4 | 95 | ≥800 | M42x1.5 | 3.5 | 225 | 510 |

Applicable Media: various refrigerants, circulated cooling water, hydraulic oil, exhaust gas and so on.

Applicable Medium Temperature: -40℃~+150℃

Maximum Working Pressure: 3.5MPa

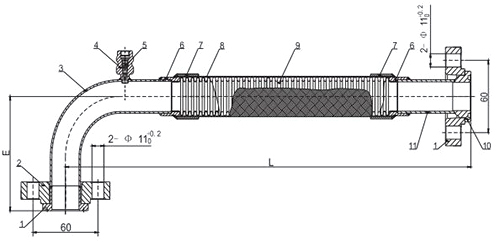

Configuration1:Both end flanged connection structure

1、bend connector; 2、flange; 3、bend; 4、fluorine infill connector; 5、valve core; 6、corrugated tube connector; 7、clamping ring; 8、braided matal wire sleeve; 9、corrugated tube; 10、sealed connector; 11、straight tube

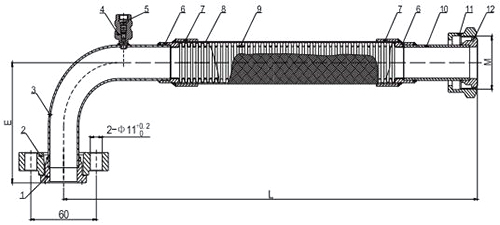

Configuration2:Combined flange and threaded connection structure

1、bend connector; 2、flange; 3、bend; 4、fluorine infill connector; 5、valve core; 6、corrugated connector; 7、clamping ring; 8、braided matal wire sleeve; 9、corrugated tube; 10、straight tube; 11、connection nut; 12、sealed connector

Features:

1. The metallic hose has a desirable flexibility with a perfect fatigue resistance.

2. The metallic hose is suitable to all types of refrigerant. Two sizes of ports, 5V1 and 6V1, are available and both high pressure version and low pressure version could be chosen for each size.

3. The metallic hose is made of stainless steel so that it eliminates the rubber hose shortcomings such as poor aging resistance, unqualified buckling, poor resistance to high and low temperature and a liable leakage.

4. The gas tightness is ensured as the metallic hose has passed the strict nitrogen gas leakage detection.

5. For the assembly of the metallic hose, first press the stainless steel connector into the flat end of the full stainless steel corrugated tube and weld them together by argon shielded arc welding. Then cover the stainless steel wire sleeve on it and clamp and fix it by the stainless steel clamping ring. Weld the metal connector, the braided metal wire sleeve and the metal clamping ring three pieces into one by argon shielded arc welding. Therefore the metallic hose features safety, high mechanical strength, corrosion resistance and heat-resistant as well as low noise and perfect shock absorption and good compensation for the heat displacement, installation deviation and foundation settlement.

6. The end of the bend is covered with rubber to enhance the flexural strength of the metallic hose. The air suction tube is covered with PU foam insulation.

7. Both threaded connection and flange connection are used to improve the installation efficiency and result and reduce the maintenance cost.