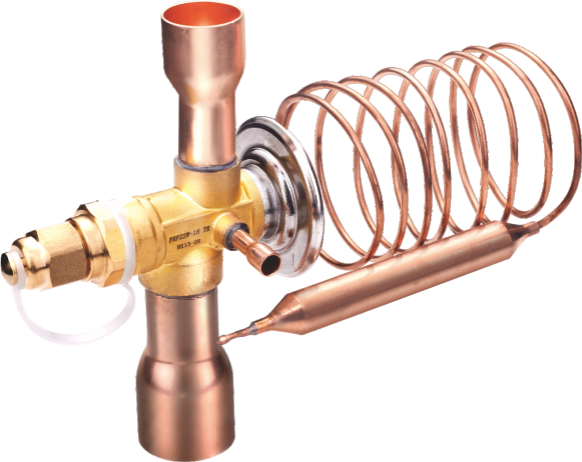

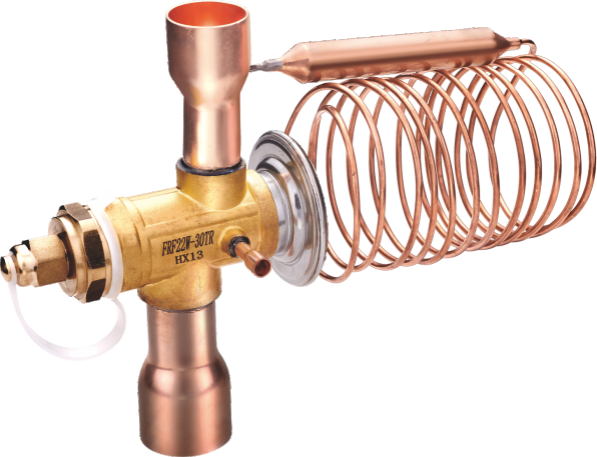

Model FRF22W、FRF134W Thermal Expansion Valve

产品详情

| efrigerant | Model | Pressure Balance | Thread(Connection Size) | Nominal Refrigerating Capacity | ||||

| Inlet | inch | Outside Balanced End | T | kW | ||||

| R22 | FRF22W-3-3-5 | —— | 3/8"ODF | 5/8"ODF | 1/4" | 3 | 10 | |

| FRF22W-3-4-5 | 1/2"ODF | 5/8"ODF | ||||||

| FRF22W-4-4-7 | 1/2"ODF | 7/8"ODF | 4 | 14 | ||||

| FRF22W-6-4-5 | 1/2"ODF | 5/8"ODF | 6 | 20 | ||||

| FRF22W-6-4-7 | 1/2"ODF | 7/8"ODF | ||||||

| FRF22W-7.5-5-7 | 5/8"ODF | 7/8"ODF | 7.5 | 27 | ||||

| FRF22W-11-5-7 | 5/8"ODF | 7/8"ODF | 11 | 38 | ||||

| FRF22W-11-5-9 | 5/8"ODF | 11/8"ODF | ||||||

| FRF22W-12-5-7 | 5/8"ODF | 7/8"ODF | 12 | 43 | ||||

| FRF22W-12-5-9 | 5/8"ODF | 11/8"ODF | ||||||

| FRF22W-15-5-9 | 5/8"ODF | 11/8"ODF | 15 | 54 | ||||

| FRF22W-15-7-9 | 7/8"ODF | 11/8"ODF | ||||||

| FRF22W-18-7-9 | 7/8"ODF | 11/8"ODF | 18 | 63 | ||||

| FRF22W-18-7-11 | 7/8"ODF | 13/8"ODF | ||||||

| FRF22W-26-7-11 | 7/8"ODF | 13/8"ODF | 26 | 92 | ||||

| FRF22W-26-9-11 | 11/8"ODF | 13/8"ODF | ||||||

| FRF22W-30-7-11 | 7/8"ODF | 13/8"ODF | 30 | 104 | ||||

| FRF22W-30-9-11 | 11/8"ODF | 13/8"ODF | ||||||

| FRF22W-38-9-11 | 11/8"ODF | 13/8"ODF | 38 | 134 | ||||

| R134a | FRF134W-3-3-5 | 3/8"ODF | 5/8"ODF | 3 | 10 | |||

| FRF134W-3-4-5 | 1/2"ODF | 5/8"ODF | ||||||

| FRF134W-4-4-7 | 1/2"ODF | 7/8"ODF | 4 | 14 | ||||

| FRF134W-6-4-5 | 1/2"ODF | 5/8"ODF | 6 | 20 | ||||

| FRF134W-6-4-7 | 1/2"ODF | 7/8"ODF | ||||||

| FRF134W-7.5-5-7 | 5/8"ODF | 7/8"ODF | 7.5 | 27 | ||||

| FRF134W-11-5-7 | 5/8"ODF | 7/8"ODF | 11 | 38 | ||||

| FRF134W-11-5-9 | 5/8"ODF | 11/8"ODF | ||||||

| FRF134W-12-5-7 | 5/8"ODF | 7/8"ODF | 12 | 43 | ||||

| FRF134W-12-5-9 | 5/8"ODF | 11/8"ODF | ||||||

| FRF134W-15-5-9 | 5/8"ODF | 11/8"ODF | 15 | 54 | ||||

| FRF134W-15-7-9 | 7/8"ODF | 11/8"ODF | ||||||

| FRF134W-18-7-9 | 7/8"ODF | 11/8"ODF | 18 | 63 | ||||

| FRF134W-18-7-11 | 7/8"ODF | 13/8"ODF | ||||||

| FRF134W-26-7-11 | 7/8"ODF | 13/8"ODF | 26 | 92 | ||||

| FRF134W-26-9-11 | 11/8"ODF | 13/8"ODF | ||||||

| FRF134W-30-7-11 | 7/8"ODF | 13/8"ODF | 30 | 104 | ||||

| FRF134W-30-9-11 | 11/8"ODF | 13/8"ODF | ||||||

| FRF134W-38-9-11 | 11/8"ODF | 13/8"ODF | 38 | 134 | ||||

Technical Parameters:

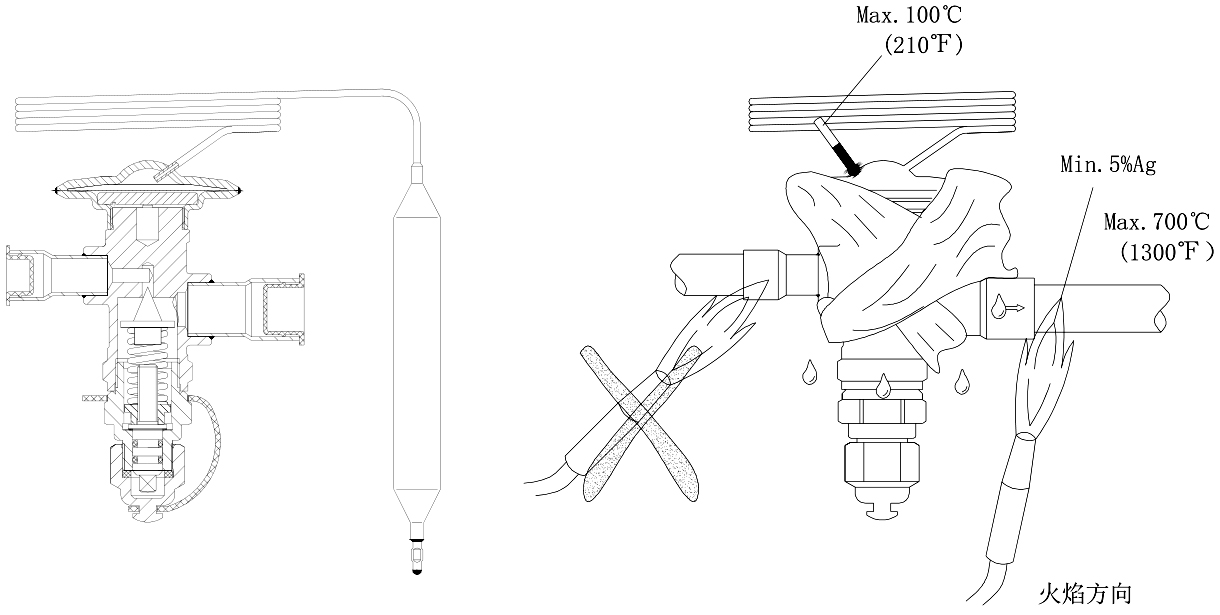

Installation and usage requirements

1) welded pipe expansion valve with the system pipe welding, we must pay attention to the following points;

1.1, use a damp cloth or a wet cotton bag to protect bodyon the body, To avoid high that temperature burn in the valve parts in welding. Please note that the 1.2 welding torch flame direction toward the body outward. 1.3 low temperature silverelectrode welding.

2) expansion valve maintenance should be designated professional staff.

| Applicable Refrigerants: | R404A、R22、R134a |

| Applicable Medium Temperature: | -40℃~+10℃、-30℃~+10℃ |

| Adjustable Range of Superheat: | 2℃~8℃ |

| Maximum Working Pressure: | 2.0MPa |

| Maximum Testing Pressure: | 3.0MPa |

Product Center

About Hongsen

News

Contact Email:

hongsen6@zjhsjx.com

Contact Us

0575-87696107

Contact address:

Refrigeration Industrial Park, Diankou Town, Zhuji City, Zhejiang Province

Fax

0575-87698985